iDSnet is an Australian made package code management platform that has been helping some of Australia’s largest manufacturers improve product traceability since 1998. This started with a simple barcode design tool to manage label-printers within manufacturing facilities, driven by innovative manufacturing practices. Today’s iDSnet has been developed as a NoCode/LowCode platform. With Matthews’ drive for continuous improvement with in manufacturing, our package code management software iDSnet enables manufacturers to ensure the right code is on the right packaging level, whether human readable or barcode, for full traceability requirements to eliminate costly human errors that lead to rework or recall of product. iDSnet data insights provides real time production information for faster, better, more informed decisions real time.

"What really made the decision easy for us [when choosing Matthews] was the fact that they were proposing a solution using their tried and tested iDSnet software, whereas others needed to build us a customised solution" - Julia Blair, Remedy Kombucha

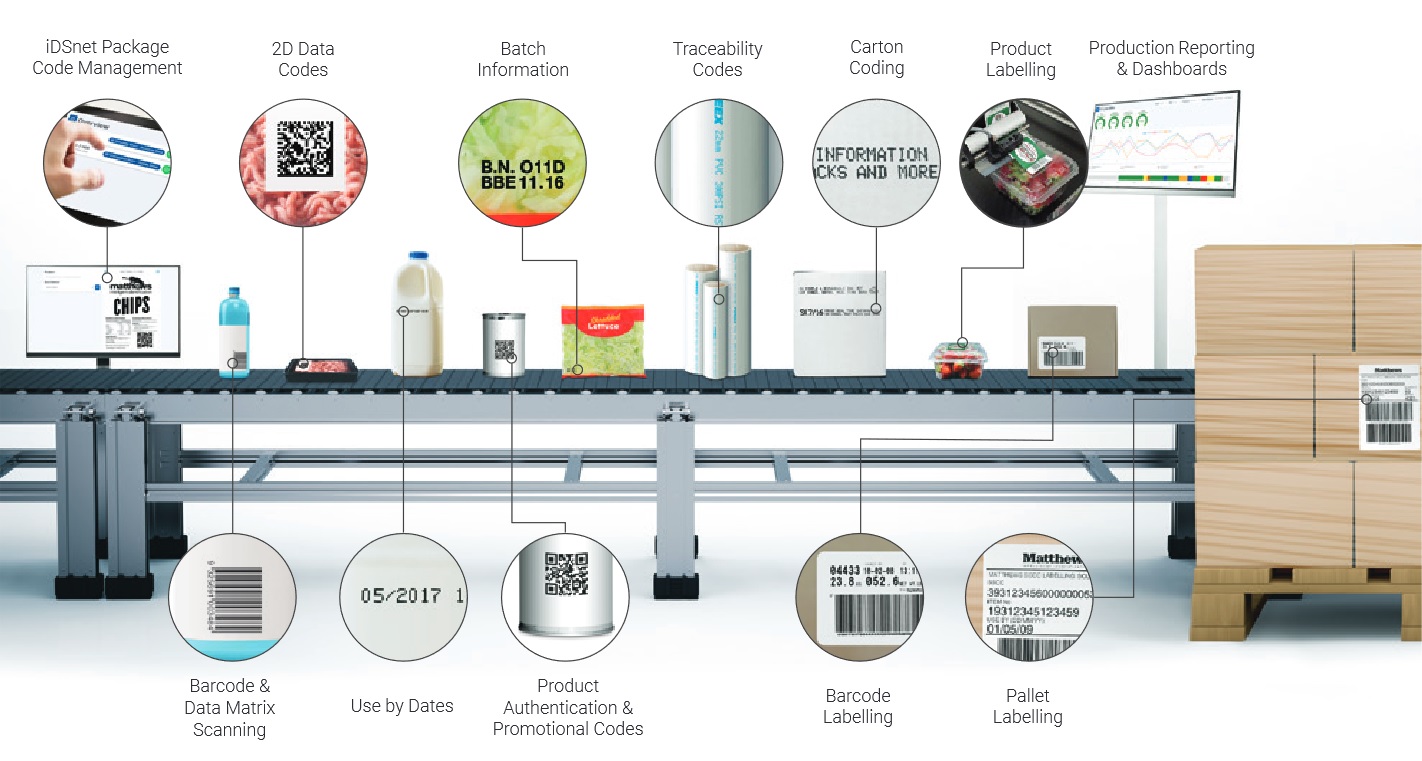

iDSnet is a complete package code management solution with the power to transform your business and provide you with the tools to increase your production efficiency. By integrating all of your coding, labelling and process equipment, such as inspection equipment, palletisers, or other supported devices, iDSnet delivers streamlined operations with quick changeovers, mitigating the risk of errors due to current manual processes.

Matthews’ iDSnet can be fully integrated into your manufacturing environment, this includes line-level equipment, externally controlled data interchanges or manually entered by operators. Seamlessly integratingwith existing ERP, SCADA and MES systems, iDSnet truly is the final piece of the puzzle for modern day manufacturing facilities to connect the production line to your enterprise business solutions. Our award-winning iDSnet software collects detailed data from your production line so you can see, interpret and communicate what’s really happening on the factory floor. With a complete view of production efficiency, downtime and quality metrics, you have actionable data to feed into your continuous improvement programs.

With industry standard open connectivity, iDSnet allows you to integrate your coding, labelling and validation into your existing ERP, WMS and SCADA systems to have truly centralised control.

By centralising the product database, work orders and the like, iDSnet ensures the correct code, such as a barcode, datecode or batchcode, is always placed on the correct product at the correct time and that the correct packaging or artwork is in use. Because all coding, labelling and other devices are networked back to a central database, product changes are achieved down an entire production line with only one simple operator action. It removes manual processes, which generally are prone to error from your end-to-end traceability, digitising them within your manufacturing environment. By capturing all of this relevant information: ingredients, batch numbers, order numbers, etc. it allows your products to run seamlessly through the supply chain.

iDSnet is fully scalable to meet your changing needs. Start with line integration for quick changeovers, data validation and error detection. Then integrate with other systems when your business grows and enjoy full overall equipment effectiveness reporting when ready.

With iDSnet, you get the peace of mind that comes from our 24x7 support, with an in-house local software team for rapid response.

We’re proud to supply premium package coding software Australia wide. Our innovative products and solutions are available across Melbourne, Canberra, Sydney, Brisbane, Darwin, Perth, Adelaide, Hobart and everywhere in between. Get in touch with our team today to see how your business can benefit.

iDSnet is a Matthews software system that helps businesses manage their production facilities from one, centralised point of control. With iDSnet you can reduce errors and increase efficiency to ensure your product reaches your customers safely.

In this video, Remedy’s Operations Manager, Julia Blair, explains why they chose to partner with Matthews: from the competitively priced, tried and tested iDsnet software, to Matthews’ project scoping and guidance in helping Remedy understand retailer requirements and industry best practice. She also talks about the value of software process-flows that match physical movements, and post-implementation augmentation to meet additional customer requirements.

Chobani Australia is the number one yoghurt company in the Australian market, located in Dandenong South, Victoria. Chobani use a variety of Matthews technology to date and batch code their products along with Matthews software to provide traceability and ease of use for operators.

"It met our need and we could see the long term benefit for our business and the quality of print it was going to give us"

"Using Matthews iDSnet [it] has accelerated product flows, significantly reduced administrative steps, increased accuracy and increased productivity across its manufacturing and distribution sites." - Mario Carniato, Kimberly-Clark Australia

Submit a quick quote request and one of our product specialists will action your request within 24hrs!