Today’s sophisticated pharmaceutical and medical manufacturers demand the highest level of supply chain traceability, branding and anti-counterfeit protection to meet with evolving global regulations and GS1 standards. Matthews full range of automated product identification and inspection products offer the capability to code and assess virtually any substrate from UV invisible inks, laser permanent marking, integrated labelers, or weighing and vision systems to assess product /code integrity.

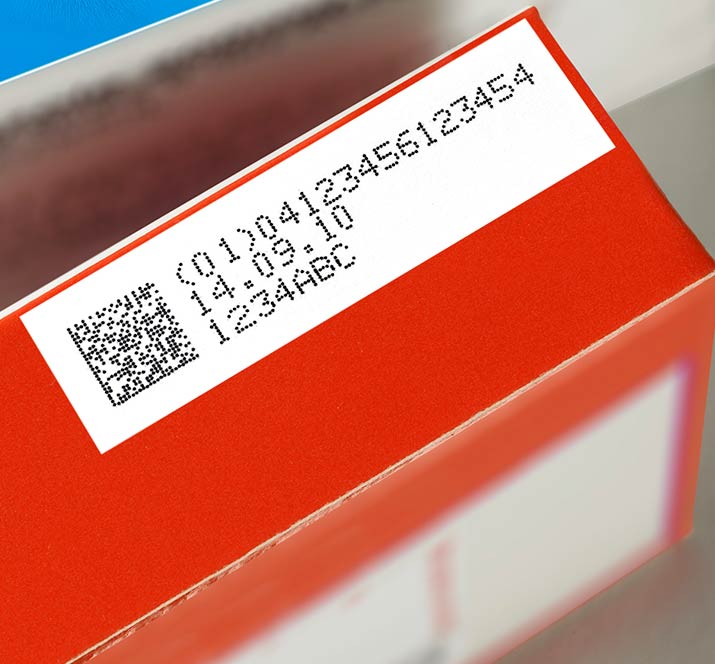

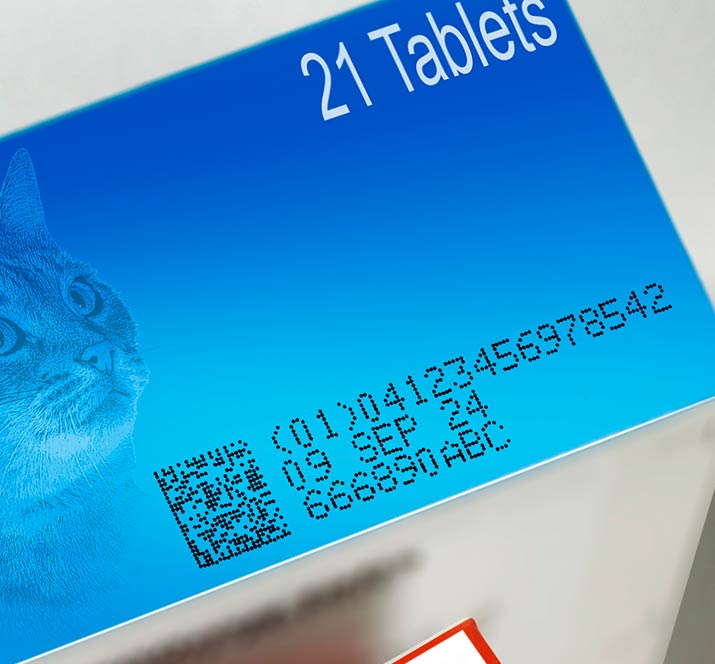

Your codes need to be highly readable and indelible to ensure product traceability and customer/patient safety, especially when it comes to coding on medicines. Matthews provides a range of coders to meet your unique coding needs, including 2D coding.

Discover the benefits of our small chracter continuous inkjet printers (CIJ), well suited to printing batch codes, date codes and best-before dates onto packaging. Both Laser coders and CIJ printers can be used to mark glass bottles.

Apply pharmaceutical labels efficiently and cost-effectively. Our range of Label Printer Applicators (LPA) and Label Applicators (LA) makes it easy to get the right label onto the right product.

Our vision inspection technology can be used to check every product before it gets shipped out to ensure it meets the quality specifications to avoid any recalls.

Whatever your pharmaceutical business needs, Matthews can provide a tailored solution to suit you. Talk to or experts to find out how.

In the pharmaceutical industry, serialisation has become a must-have to combat counterfeiters. Over the years, counterfeit pharmaceutical products have posed an increasing risk to patient safety, as well as resulting in lost revenue and brand damage for manufacturers.

Matthews helps you introduce unique identification for each and every pack of pharmaceuticals, so you can tighten the security of the supply chain and protect against counterfeiters. The result is significantly improved patient safety and brand integrity.

We’re proud to supply premium coding and labelling systems including solutions for pharma barcodesand software Australia-wide. Our innovative products are available across Melbourne, Canberra, Sydney, Brisbane, Darwin, Perth, Adelaide, Hobart, and everywhere in between. Get in touch with our team today to see how your business can benefit..

Submit a quick quote request and one of our product specialists will action your request within 24hrs!