May 14, 2021 by Mark Dingley

Do you rely on manual operators to manage product labels and codes? What happens when they make a mistake?

Simple errors in coding and labelling can be expensive for manufacturers. They can result in product recalls, reworks, and rejections, leading to more waste.

The number one reason for coding and labelling errors?

Humans.

The reality is that manually entering data, text, or images onto packaging or labels often leads to mistakes. A worker can be expected to make one mistake for every 300 touches, on average. And when you’re coding and labelling hundreds or thousands of products, that’s a high potential for error.

It might be an error in label selection, resulting in the wrong information being put onto product packaging, or an error in package code management, such as entering the wrong information in a label template.

That’s where a package code management system can help.

In this article, we explain what package code management is and how it can help Australian manufacturers reduce costly errors and drive efficiencies.

Package code management is about ensuring that the right code is placed on the right product, at the right time, every time. The software provides a centralised point from which you can draw on product information to create labels and codes, and manage label application onto products.

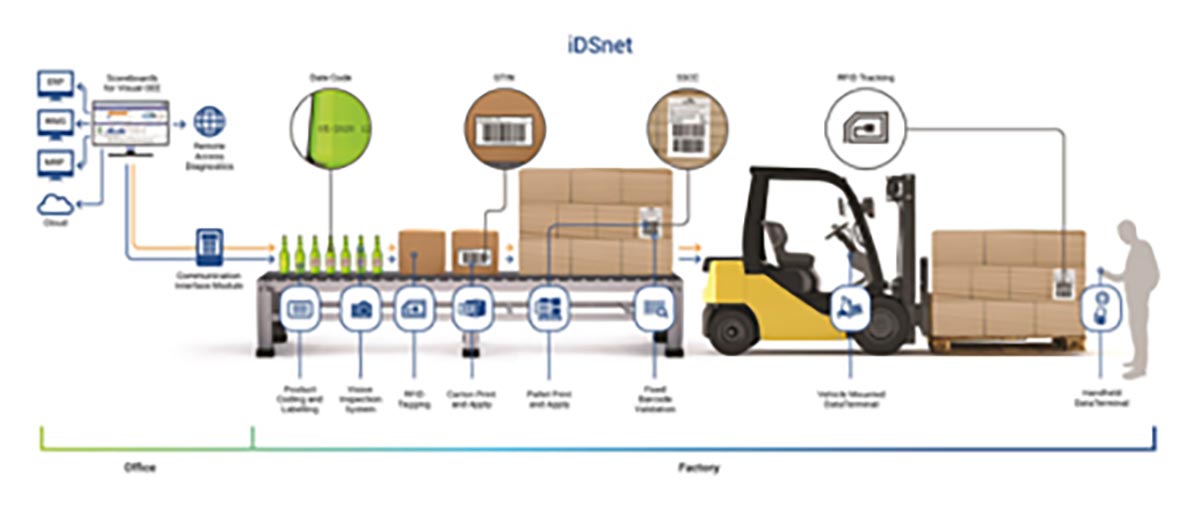

One example of package code management software is iDSnet.

iDSnet is a Matthews software system that helps businesses manage their coders, labellers and inspection equipment from one centralised point of control. This eliminates the need for operator intervention and reduces the number of coding and labelling errors.

It provides one central point of control

At the most basic level, a package code management system can allow you to design labels or codes, and ensure the right code goes on the right product, across multiple product lines from one central location.

This reduces the number of manual data entry points, thereby cutting the risk of errors.

A manager or operator can simply go to one place to run all pieces of equipment – a coder, label printer applicator and barcode scanner. This is especially important if you have multiple manufacturing sites. Let’s say you have lots of sites across Australia – rather than relying on operators in each site to use the right labels for the right products, you can design and control all labels from one place. That way, wherever they’re printed, they always look the same.

Use a single source of truth for the most accurate, up-to-date labels

What happens when product information has been updated in the central system, but that information hasn’t cascaded down to the packaging line? Your products wind up with the wrong information on their labels, and you need to scrap them.

That’s not a problem with iDSnet Enterprise. Codes can be managed through your existing ERP/MRP system and synchronised to iDSnet. If information is updated on the master file, it is live on iDSnet within a second. So, there no risk of a lag on the packaging line causing coding errors. You always have pure data right from the source.

A package code management system can also prevent errors on the label design. iDSnet has a message design tool that allows operators to create and edit labels and inkjet formats, so you can prevent errors before they are printed.

Introducing label templates reduces the number of labels required on lines to make it simpler for operators involved in code selection. If you need to change the labels due to legislation updates, it’s also much faster and easier with label templates.

You can also decide who can change labels and set up permissions to control access. iDSnet lets you create and maintain user groups, with user privileges able to be limited as print-only users.

A package code management system allows you to manage, upload and download formats from one centralised database. There’s no need to remember to make changes in multiple areas of the production line – operators only need to make the change in one place, which streamlines your processes and saves valuable time.

Find out how you can use iDSnet to reduce labelling and coding errors. Watch how iDSnet has helped leading yoghurt brand Chobani eliminate manual operator intervention and drive efficiencies in their business

Chobani Australia - Customer Testimonial