Coding on substrates like plastic, metal or even flexible tube and working in challenging manufacturing environments requires reliable solutions. Matthews’ pipe coding equipment is designed to perform consistently with minimal maintenance and downtime.

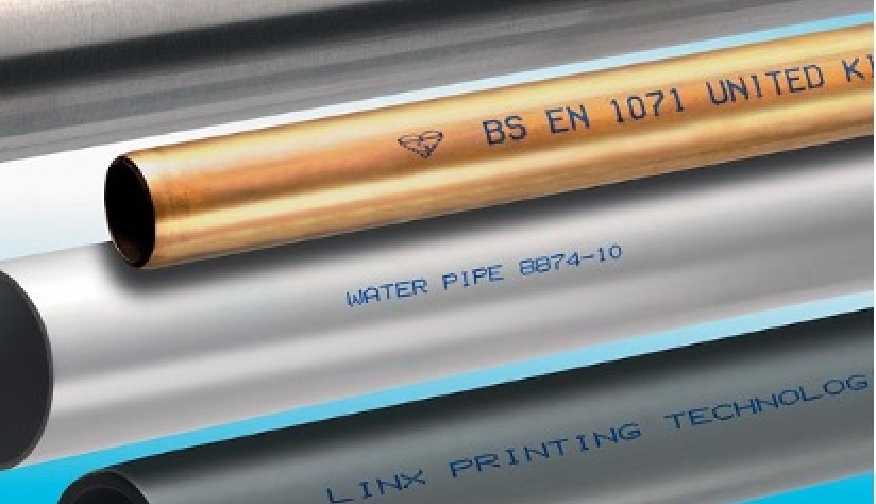

For the piping, tubing, pipe extrusion, and related industries, meeting regulatory requirements, batch tracking, and maintaining codes throughout the supply chain are key. Technologies like inkjet printing and laser marking can be adapted to suit specific products and their applications, supporting traceability, quality control, and compliance with industry standards.

Our team has extensive experience in the piping and tubing sector and can help identify the right solution for your operational needs.

Plastic pipes can be made from different types of plastic, including PVC, PE, PP, and more. Accurate material identification is essential for quality control and compliance. Printing or coding on plastic surfaces can be challenging due to their smooth and non-porous nature so ensuring that codes adhere properly without smudging or fading is crucial. Outdoor applications may also require codes that are resistant to UV exposure, weather and abrasion to reduce fading and maintain readability over time.

Our systems also support water pipe marking, ensuring reliable identification and traceability for pipes used in potable water and irrigation applications.

Coding systems must accommodate different tubing materials, each with its own coding requirements. Flexible tubing and hose can be made from a wide range of materials, including rubber, silicone, thermoplastics, and more. They must also be versatile enough to handle tubing of various diameters, lengths, shapes, and colours, ensuring accurate marking across all material types and configurations.

The pipe industry may deal with various types of metals, such as steel, stainless steel, aluminium, and copper. Coding systems must distinguish between these materials. Metal pipes can be exposed to corrosive environments; therefore, codes must withstand corrosion and remain legible to ensure traceability.

In addition to durability, traceability is essential. That’s why our systems also enable barcode printing on steel pipes and labelling on metal tubing, ensuring every component can be scanned and tracked, even in corrosive or outdoor environments.

.jpg)

Concrete pipes are used in large-scale projects like drainage, sewer, and stormwater systems. These pipes are often stored outdoors, so codes need to be durable and easy to read in tough conditions.

Because concrete has a rough surface, applying clear codes – like pipe specification code, manufacturing date, batch number etc – can be tricky. Matthews offers purpose-built concrete pipe marking system using Drop-on-Demand (DOD) inkjet printers that can print directly onto concrete.

With flexible and easy to use coding and marking solutions, you can not only ensure you have the right codes for your products, but also increase productivity, eliminate waste and improve your bottom line. Contact us to discuss the right coding and marking solution for your tubing and piping business.

.png)

| Acronym | Material Name | Common Applications | Typical Code Markings / Standards |

|---|---|---|---|

| RCP | Reinforced Concrete Pipe | Stormwater drainage, culverts, sewer systems | AS/NZS 4058 (Precast concrete pipes), AS/NZS 3725 (Installation of buried concrete pipes) |

| FRC | Fibre Reinforced Concrete Pipe | Stormwater drainage | AS 4139 (Fibre reinforced concrete pipes), AS/NZS 3725 |

| PCCP | Prestressed Concrete Cylinder Pipe | Large-diameter water transmission pipelines | AWWA C301 (Prestressed concrete pressure pipe), AS/NZS 4058 |

| HDPE | High-Density Polyethylene | Water supply, gas mains, sewer rising mains, stormwater drainage | AS/NZS 4130 (Polyethylene pipes for pressure applications), AS/NZS 2033 (Installation) |

| PVC | Polyvinyl Chloride | Water supply, sewerage, stormwater drainage | AS/NZS 1477 (PVC pipes and fittings for pressure applications), AS/NZS 1260 (PVC pipes for non-pressure applications) |

| DICL | Ductile Iron Cement Lined | Water supply, sewer rising mains | AS/NZS 2280 (Ductile iron pipes and fittings) |

| SS | Stainless Steel | Corrosive environments, food and beverage processing, medical gasess | AS 5200.053 (Stainless steel pipes for plumbing applications) |

| GRP | Glass Reinforced Plastic | Chemical processing, sewer mains, corrosive environments | AS 3571 (Glass reinforced thermosetting plastics (GRP) pipes) |

| ABS | Acrylonitrile Butadiene Styrene | Drainage, waste, and vent systems | AS/NZS 3518 (ABS pipes and fittings for pressure applications) |

| PE | Polyethylene | Water supply, gas distribution, irrigation | AS/NZS 4130 (Polyethylene pipes for pressure applications), AS/NZS 2033 (Installation) |

| CS | Carbon Steel | High-pressure water, gas, structural applications | AS 1579 (Arc-welded steel pipes and fittings for water and waste water), AS 4041 (Pressure piping) |

| SSCL | Stainless Steel Cement Lined | Potable water systems, industrial applications | AS 5200.053 (Stainless steel pipes for plumbing applications) |

| HDG | Hot-Dip Galvanized Steel | Structural applications, water supply | AS/NZS 4792 (Hot-dip galvanized coatings on ferrous hollow sections) |

| PP | Polypropylene | Industrial piping systems, chemical processing | AS/NZS 5065 (Polypropylene pipes and fittings for pressure applications) |

| PB | Polybutylene | Hot and cold water plumbing | AS/NZS 2642 (Polybutylene pipes for pressure applications) |

| PEX | Cross-linked Polyethylene | Hot and cold water plumbing, hydronic heating | AS/NZS 2492 (PEX pipes for pressure applications) |

| RC | Reinforced Concrete | Stormwater, culverts, large-diameter sewer systems | AS/NZS 4058 (Precast concrete pipes), AS/NZS 3725 (Installation of buried concrete pipes) |

| DI | Ductile Iron | Water mains, sewer rising mains | AS/NZS 2280 (Ductile iron pipes and fittings) |

| GMS | Galvanized Mild Steel | Fire services, structural applications | AS/NZS 1074 (Steel tubes and tubulars for ordinary service) |

| SS | Stainless Steel | Stainless Steelonments, food and beverage processing, medical gases | AS 5200.053 (Stainless steel pipes for plumbing applications) |

We’re proud to supply premium coding and labelling systems and software Australia wide. Our innovative products and solutions are available across Melbourne, Canberra, Sydney, Brisbane, Darwin, Perth, Adelaide, Hobart and everywhere in between. Get in touch with our team today to see how your business can benefit.

Submit a quick quote request and one of our product specialists will action your request within 24hrs!