Nov 22, 2022 by Mark Dingley

If you’re supplying products to major retailers such as Woolworths, K-Mart and Big W, you have probably heard about cross-dock.

While it’s not new, Australian retailers are increasingly adopting the logistics standard to keep stock moving, save on storage costs, and improve process efficiencies.

So, what exactly is “cross dock”? How does it work? And how can suppliers tick the boxes for those retailers using cross-dock?

In this article, we’ll explain what you need to know.

The name “cross-dock” refers to the process of receiving products into an inbound dock and transferring them “across the dock” to the outbound terminal ready for transportation.

So cross docking is where products are distributed from a supplier to a retail outlet, with minimal handling or storage time in a warehouse or distribution centre (DC).

Here’s how it might work:

First, your pallet of products arrives on truck into the inbound dock.

Here, it’s sorted and consolidated at the cross-docking terminal. Bigger loads are broken down into smaller shipments and consolidated with other products going in the same direction or to the same retailer outlet.

Then the pallet is quickly loaded onto an outgoing vehicle at the outbound dock to be transported to the retailer.

Cross-docking provides lots of benefits around speed and efficiency. The process reduces manual input, speeds up logistics and helps get products on the shelf faster. In short, products move in and out of the warehouse in no time.

The less stock held in the warehouse, the more money a retailer can save – especially because inventory storage costs can be as high as two-thirds of total warehousing costs. A cross-dock warehouse uses a smaller footprint than a traditional warehouse or DC, which saves on real estate.

For suppliers, cross-docking means pallets are utilised more efficiently, and there’s a reduction in transport because you can combine multiple smaller product orders into one transportation to save on costs. It also means less damage to products because they aren’t held in the warehouse.

Cross-dock is especially beneficial for smaller vendors distributing lower product volumes relative to larger suppliers.

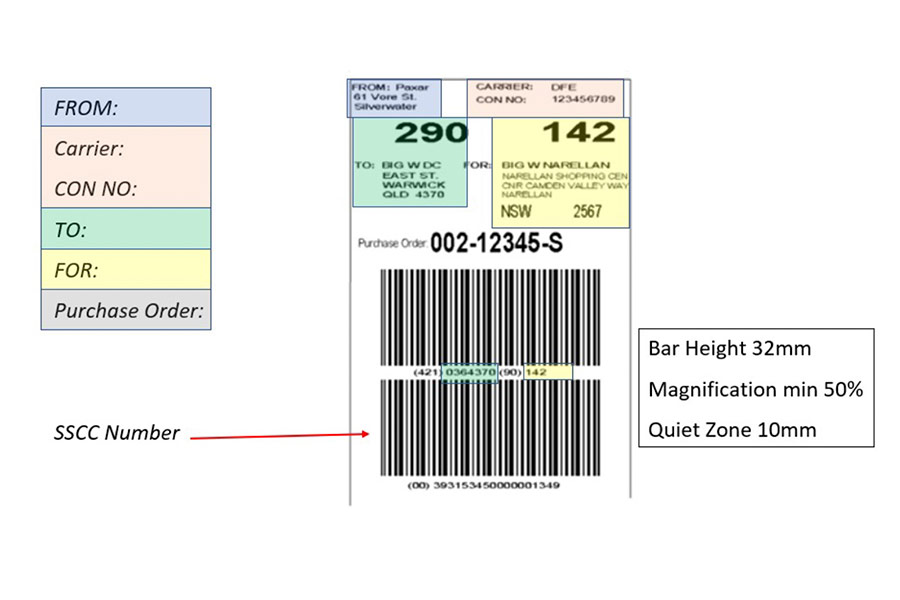

An example of an SSCC label.

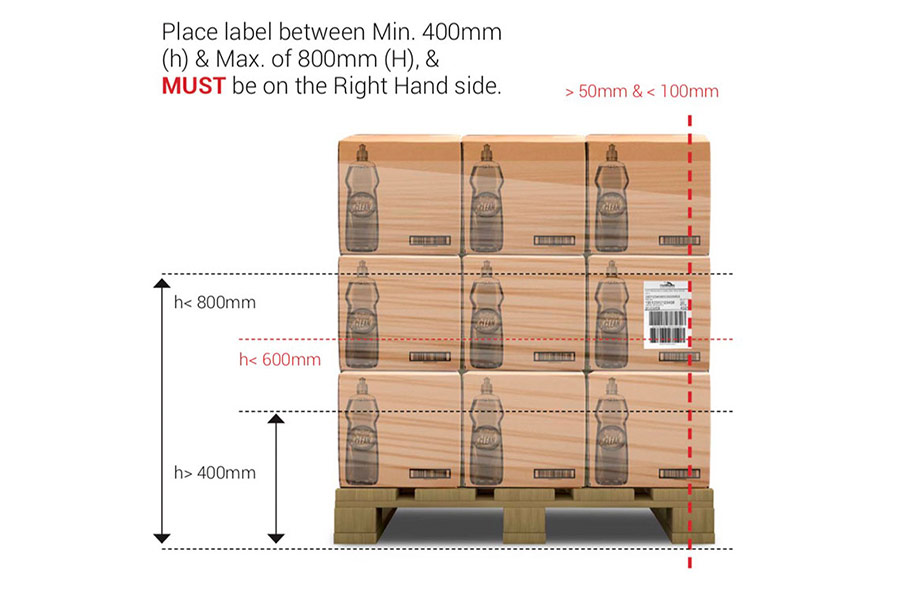

An essential element in cross-docking is the label.

A cross-dock label is a single label that includes multiple destinations, such as the DC and the retail outlet where the product will ultimately be sold.

Because the label clearly defines the goods’ final destination, it reduces manual handling and human-error risk. The same logistics item can be used to move the product through to the end retailer.

Another point to note is that unlike a normal SSCC label, where you can only have one SKU per label, a cross-dock item can contain multiple SKUs.

No… not yet. But it’s becoming more commonplace, and is likely to become mandatory for suppliers to some retailers in the future. So, suppliers should be ready now.

An example of a cross-dock label.

No, unfortunately. Different retailers use slightly different label formats.

However, the good news is that you can easily create compliant cross-dock labels using iDSnet Cloud.

iDSnet Cloud is a cloud-based printing tool which makes it easy to generate and print carton, crate, SSCC and cross-dock labels. With Matthews’ simple-to-use software, you can be confident your labels are compliant with major retailer standards and will be accepted at the DC.

Learn more about Cross Dock and the labelling requirements in our Barcode Learning Centre.