May 14, 2024 by Mark Dingley

If you’re a grower looking to supply Woolworths Group with your fresh produce, the rules can be overwhelming. So how can you ensure your products are accepted into DCs without any headaches?

Woolworths Group calls itself the “The Fresh Food People” for good reason. The company has strict standards for its fresh produce suppliers, ensuring its customers can buy the freshest and safest produce possible.

We invited Julian Laxamana, a supplier specialist from Woolworths Group, to our Retailer Engagement Hub at APPEX 2024 to share the top things fresh produce suppliers need to know to stay compliant.

Woolworths launched its produce delivery requirements in 2021, with the aim to enhance the quality and safety of produce items it receives from suppliers.

The biggest focus is on two areas:

1. Carton and crate labelling

2. Pallet-wrapping requirements

Let’s take a look at the details.

For many fruit and vegetable suppliers, carton and crate labelling is a brand-new space that you may never have considered.

Here are some essential things to focus on:

Woolworths Group heavily relies on the GTIN barcoding of trade units (cartons/crates) to identify products through the supply chain and in-store back-of-house processes.

The placement of carton GTIN barcodes is essential to ensure that team members can quickly identify stock at first glance and don’t have to waste time trying to locate a barcode.

The rules around how and where GTIN barcodes must be applied depend on the type of carton or crate you are using:

In addition to the GTIN barcode, Woolworths Group requires additional information to be printed on the crate or carton label to ensure the team members can quickly identify the contents throughout the supply chain networks and in stores.

While not all fields are relevant to every category, required information can include:

Check Woolworths’ requirements for details of what’s needed on your produce carton labels.

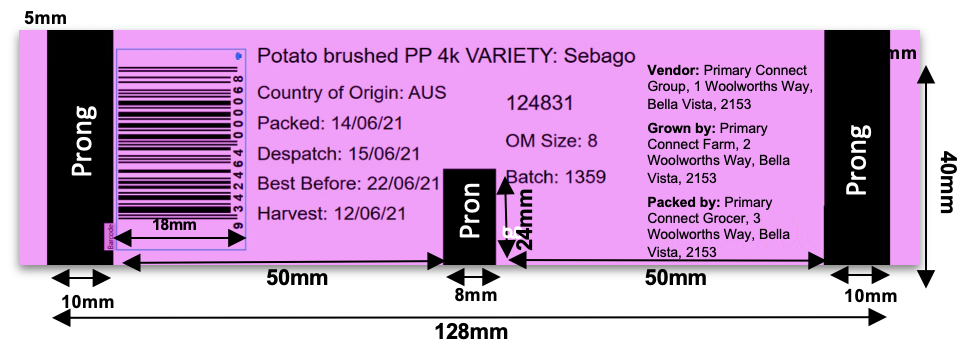

Pro Tip: When applying the label on the carton, make sure the prongs don’t obscure the information and cause a non-conformance issue.

Some produce, such as chestnuts, cherries, strawberries and apples, must be temperature-controlled throughout the supply chain.

To make it easy for team members to identify this and ensure food safety, these products must have a crate/carton label printed on pink paper.

For consistency, Woolworths is particular about the shade of pink, too: it must be Pantone Pink #182C.

Pallet wrapping is crucial for fresh produce suppliers looking to supply to Woolworths Group.

Here’s a breakdown of the pallet wrapping requirements:

Fresh produce isn’t like other products, as many fruits and vegetables must be kept cool throughout the supply chain. Ventilation is essential to reduce humidity, prevent mould formation, and prolong the shelf life during transit and storage.

Woolworths allows specific pallet-wrapping techniques for fresh produce to allow for maximum airflow without compromising the pallet’s stability and safety:

This preferred method can be used with standard pallet stretch film to allow maximum airflow while ensuring the pallet remains stable as it moves through the supply chain network.

Requirements when using the butterfly wrapping technique:

Image: Butterfly stretch-wrapping technique

Image: Butterfly stretch-wrapping techniqueYou can use low-adhesion stretch tape to hold palletised goods during transport and storage and some stretch wrapping to secure the stock.

If you use low-adhesion stretch tape, you must:

Image: Low-adhesion stretch tape and wrapping combination

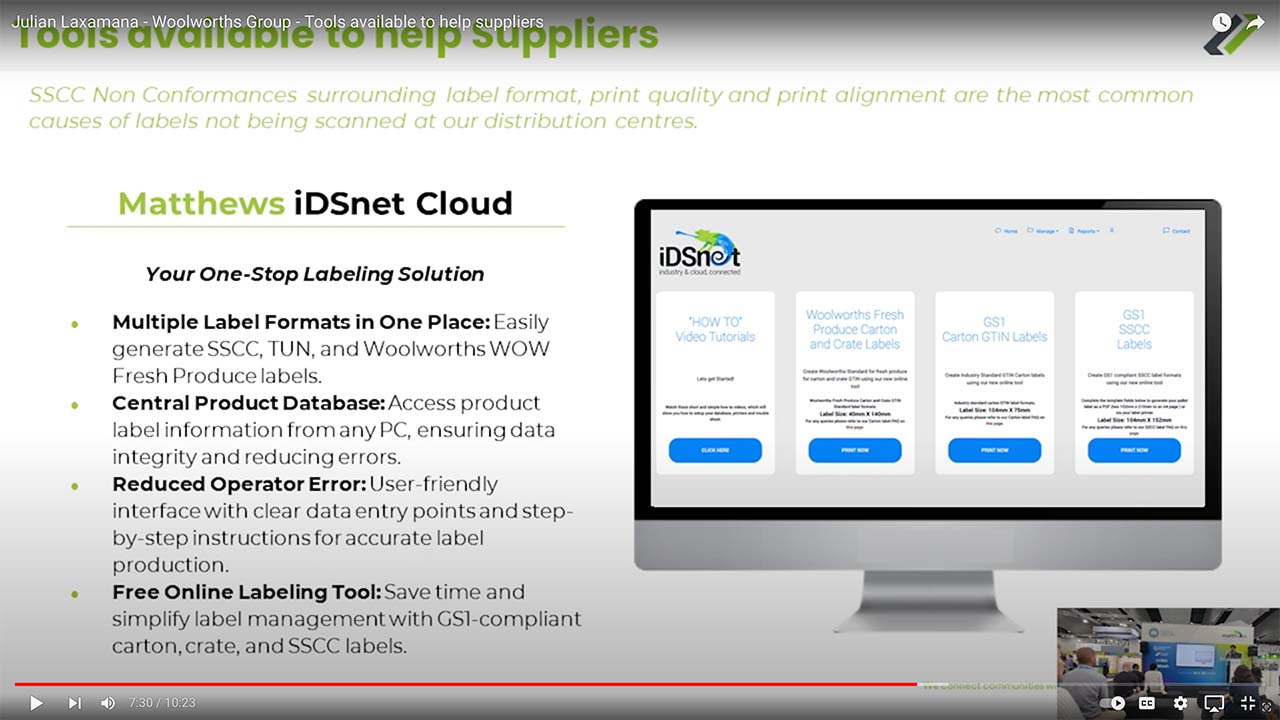

Image: Low-adhesion stretch tape and wrapping combinationDon’t let labelling become a compliance issue. Matthews offers a cloud-based printing tool to remove the stress of supermarket labelling compliance for fresh produce suppliers.

Created in collaboration with Woolworths Group Supply Chain and GS1 Australia to prevent coding and labelling issues, our iDSnet Cloud software has a free, entry-level version for manufacturers, including fresh-produce suppliers. iDSnet Cloud generates and prints Woolworths fresh produce labels for your crates, cartons or pallets, so you can be confident your products will be accepted at the DC.

Start using iDSnet Cloud now or talk to our team to see how we can help you stay compliant with Woolworths and other major retailers.