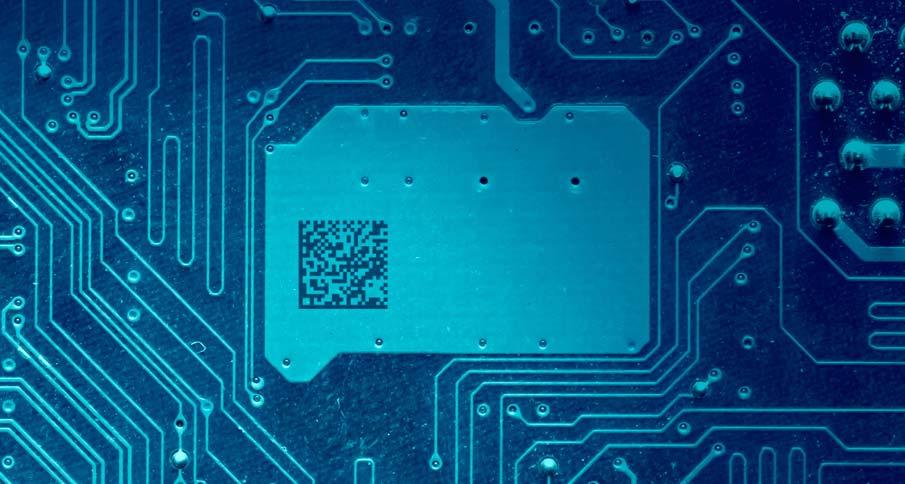

How do you mark parts and components, in particular smaller items with limited available space to apply a code? Our Datamatrix factsheet has everything you need to know about using GS1 DataMatrix barcodes.

GS1 DataMatrix is a compact, two-dimensional barcode which holds a large amount of data in a small space.

At its maximum, a DataMatrix symbol can store 2,335 alphanumeric characters, which may include manufacturer ID, a unique serial number and more.

The most common use of DataMatrix barcodes is marking directly onto small parts, such as electronic and circuit board components, as it enables a large amount of data to be contained in a very small space.

Data Matrix - Marking of Small Items and Components

GS1 DataMatrix is extensively used in the pharmaceutical and healthcare industries for anti-counterfeiting applications and asset tracking (ie; for medical devices).

Data Matrix Medical Instruments and Surgical Implants LR

One of the first organisations to use DataMatrix codes was NASA in the ‘80s. NASA engraved codes onto parts of space rockets knowing the codes wouldn’t come off.

Data Matrix Marking of Small Items and Components

The Datamatrix is used to contain variable data to reduce operator scan time and the risk of selling expired or recalled products. The value of being able to uniquely identify and recall a specific product pack of fresh produce (instead of the entire batch) is significant.

Data Matrix Fresh Produce

GS1 Datamatrix is regulated by the GS1 global standards body. It uses a Function 1 Symbol Character (FNC1) at the beginning of its code that acts as a special start sequence that differentiates it from a normal Datmatrix.

The GTIN-14 is only for groupings of the same items. In other words, all products contained in the carton/case are identical.

DataMatrix is designed for industries that require parts marking, such as aerospace, automotive, semiconductor,medical instruments and fresh produce. The global healthcare industry has identified DataMatrix as its long-term preferred barcode.

In some circumstances it can, for example in some supermarkets the Datamatrix has replaced the EAN-13 in fresh produce and meat.

Camera-based barcode scanners are required to read GS1 DataMatrix codes. Normal 1D barcode scanners cannot read 2D barcodes.

The size of the DataMatrix barcode is determined by the amount of data to be encoded. The square symbol can be as small as 10x10 and as big as 144x144 modules. The rectangular symbol can vary between 8 - 18 modules/rows and 16 – 48 modules/columns.

The smallest size of GS1 DataMatrix is 10 x 10 modules.

Like other barcodes, DataMatrix is made up of a string of GS1 Application Identifiers. For example, 01 for GTIN, 10 for batch or lot number, 21 for serial number, and so on. Go to GS1 Australia’s website for a full list of AIs.

Laser is a suitable option for printing indelible and permanent DataMatrix codes onto a wide range of substrates, such as plastic, glass, paper, cartons and metals.

Other options include thermal transfer, inkjet and direct part marking (e.g. engraving).

Whilst we attempt to update this page as changes occur we do not guarantee its accuracy and recommend that you contact GS1 Australia for the most up to date advice.