Our simple to use cloud based printing tool to generate and print carton, crate & SSCC labels.

iDSnet Cloud has taken the hassle out of needing to use different software for different label formats. Now you have access to software that can produce your SSCC, GTIN and Woolworths WOW Fresh Produce labels all in the one place for easy access and an increase in efficiency.

iDSnet Cloud allows you to see your products label information from any PC, in any location. This helps to keep data integrity, reduces data corruption and label errors as it eliminates the need for multiple files to be kept in different locations where information could become mismatched and is not updated when label information changes.

A platform that helps you to easily distinguish which label format is the right one to use for your application, clearly marked data entry points and with step-by-step instructions available, the iDSnet Cloud platform is easy to use so your operators can produce barcodes and labels in-line with industry standards, every time.

iDSnet Cloud takes the stress out of supermarket labelling compliance, ensuring a more accurate way to meet various supermarket and major retailer standards. Print compliant SSCC, GTIN, cross dock and Woolworths fresh produce labels for your crates, cartons or pallets. Keep track of labels more accurately and be confident products will be accepted at the DC.

Need to know more? Find out more about the standards on our Barcode Learning Centre and test your knowledge with our Barcode Academy.

iDSnet Cloud has simplified the process of generating various label types, allowing you to generate and print your compliant tickets, tags and labels all from the one platform. You’ll no longer need countless software platforms for different label formats.

Print a range of GS1 labels, anywhere, at anytime. iDSnet Cloud is a cloud-based platform, which means you can design, print and manage multiple labels from any device with an internet connection. Look no further than this centralised database to store and manage product, grower, packer, and batch information.

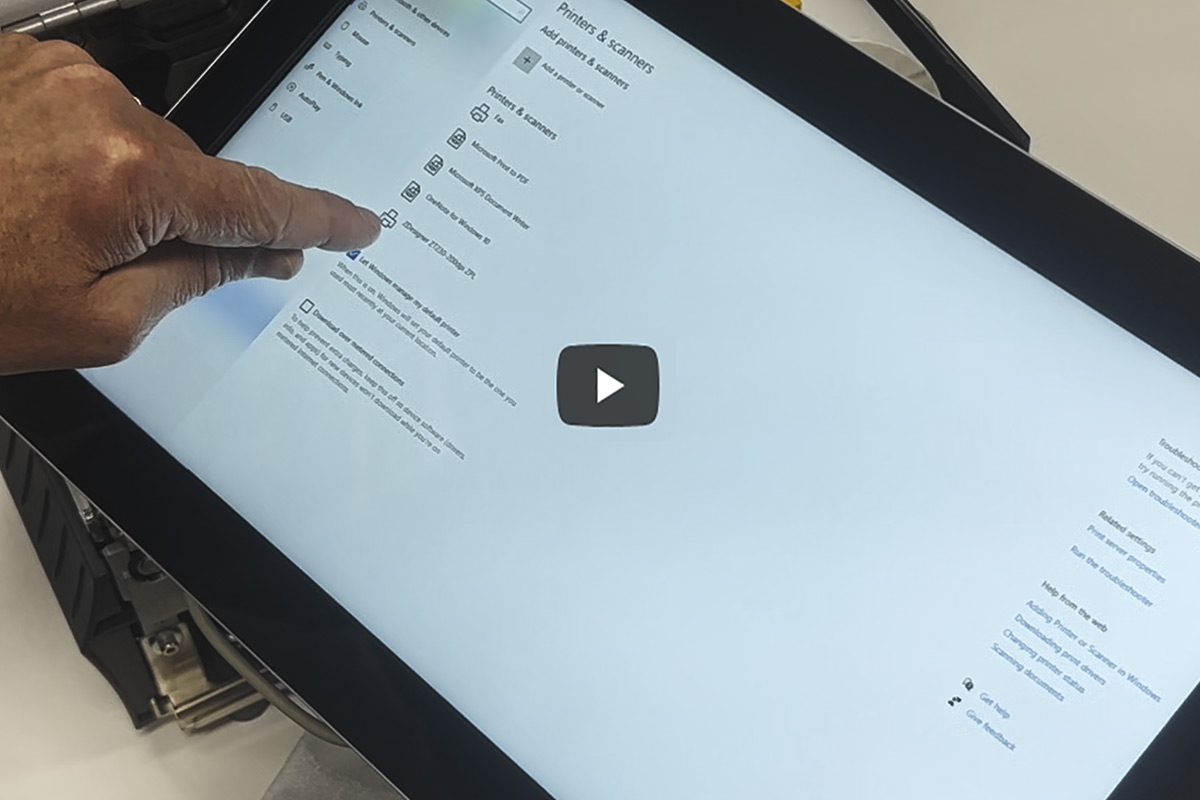

The first step in creating and printing labels that meet supermarket standards is to make sure your PC is set up with the correct software. In this video we give you the step-by-step instructions on to how to add Java and QZ software to your PC, so you can get started with iDSnet Cloud.

Link to the Java Software: java.com

Link to the QZ Software: http://qz.io/

Step two is using the iDSnet Cloud platform to create your labels. In this video we guide you through how to enter your product data, your users, and printer information into the iDSnet Cloud platform, along with how to create and print the labels ready for applying to your products.

Get started by going to; https://idsnetcloud.matthews.com.au/

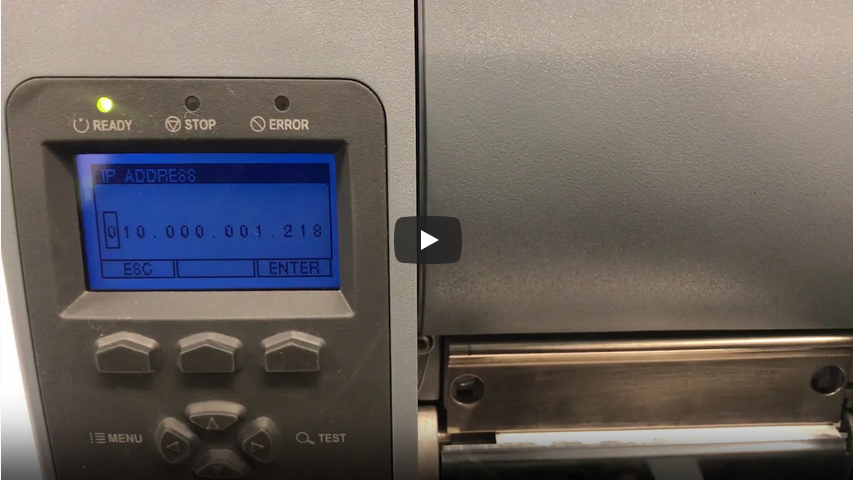

To create and print labels that meet supermarket standards you need to have a printer that is set up correctly. This video gives you the step by step instructions on to how successfully set up your Datamax 4206 Printer for iDSnet Cloud.

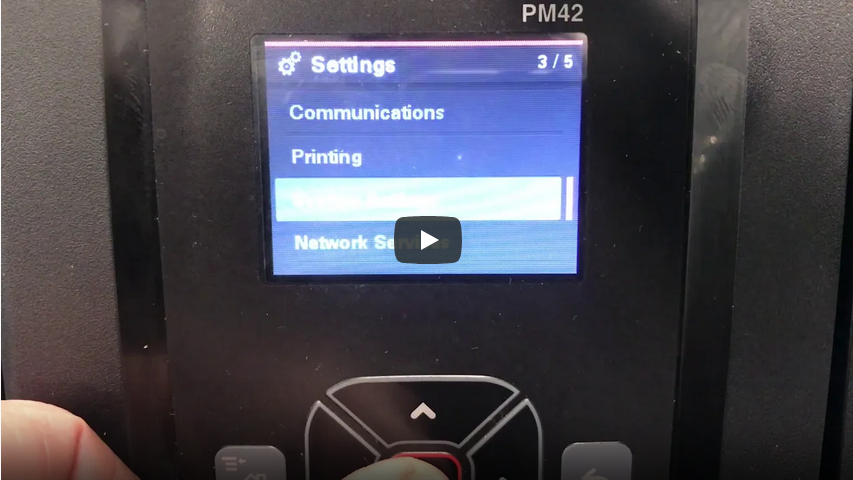

To have product and shipping labels that meet supermarket standards you need to have your printer set up correctly. This video demonstrates how to set up your Honeywell PM42 printer for iDSnet Cloud.

This video gives you a step by step guide on how to successfully set up your Desktop Printer for iDSnet Cloud, so you can get started with creating and printing labels for your products that meet supermarket standards.

This video demonstrates how to successfully set up a Windows Print Driver with iDSnet Cloud, so you can connect your printer and get started with creating and printing labels for your products.